Restore Operational Stability in 90-120 Days

When your pharmaceutical manufacturing operations are off-track, GMPKit deploys our proven approach, expert network, and digital tools to turn strategy into disciplined execution—fast.

When Manufacturing Strategy Breaks Down

GMPKit engages when operational crises threaten your site performance. Which challenge are you facing?

Batch Success

Low first-pass success rates driving up COPQ and delaying product delivery

Backlog Reduction

Growing deviation and investigation backlogs creating regulatory risk

Scale-Up

Struggling to scale from clinical to commercial manufacturing volumes

Inspection Readiness

FDA inspection imminent or findings requiring rapid remediation

Process Optimization

Inefficient business processes and workflow bottlenecks limiting batch throughput

Complex Deviation

Investigation stalled on complex deviation requiring specialized expertise

The GMPKit Approach to Strategy Deployment

We deliver results faster than internal teams by bringing the right approach and toolset to restore operational stability in 90-120 days.

Scope & Discovery

Understand strategic intent and diagnose current state

Strategy Translation & Toolkit Selection

Match the right tools to your specific challenges

Implementation

Partner with your site teams to deploy solutions in 90-120 days

Improvement Monitoring

Ensure sustainable results

Hover over or tap any step to learn more

Our Toolkit: Experience, Tools, and Expert Network

Our experience, tools, and SME network help us solve problems quickly—getting your strategy back on track.

Diagnostic Frameworks

Identify gaps that cause strategy to fail across leadership, compliance, operations, and quality

SME Network

Expert intervention when your team is stuck—deploying specialized expertise to unblock progress

Benchmarking Intelligence

Understand industry standards and turn operational reliability into a competitive advantage

Leadership Development

Build critical skills to deploy strategy in highly regulated GMP environments

"Sprint" Governance Model

LEAN + PDCA + Agile governance framework for weekly planning, execution, and strategy checks

LEAN Frameworks

Structured problem-solving approaches perfected for pharmaceutical manufacturing

BatchTrak™ Platform

Digital visibility and accountability for batch operations—streamlining disposition and driving actions

Consulting + Agency Model

Unlike traditional consultants who provide advice, we partner directly with your site teams and assume accountability for measurable results.

90-120 Day Commitment

We deliver measurable results in 90-120 days, not 6-12 month projects. When your manufacturing network is in crisis, speed matters.

Execution, Not Just Advice

We work alongside your site teams to execute solutions—not deliver recommendations and leave. We assume accountability for results.

Expert Intervention

We deploy our SME network when your team needs specialized expertise or bandwidth—bringing process development, quality, and operations experts.

Proven Across CDMOs

Validated across mid-size CDMOs, biopharma sites, cell therapy operations, and gene therapy facilities—we understand your challenges.

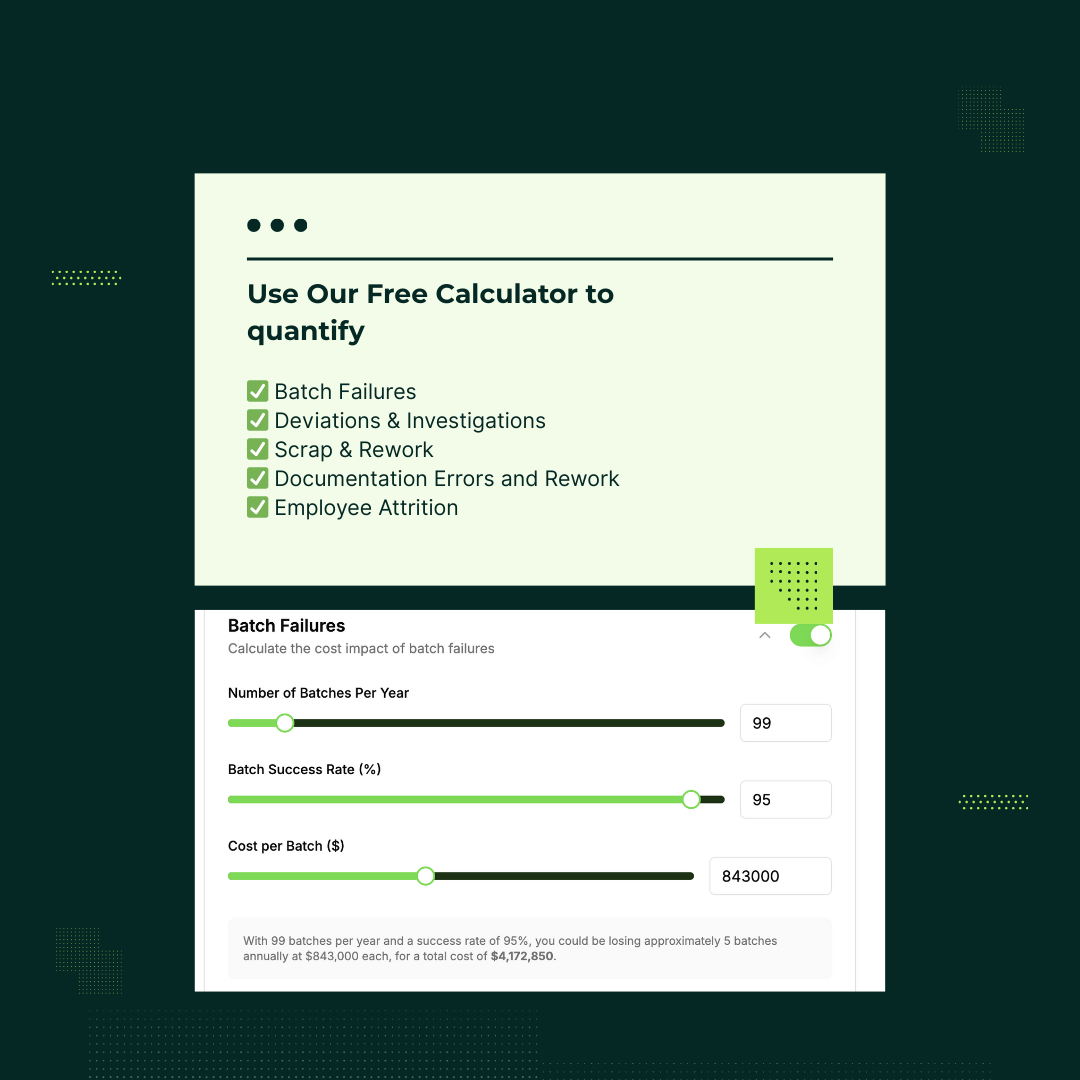

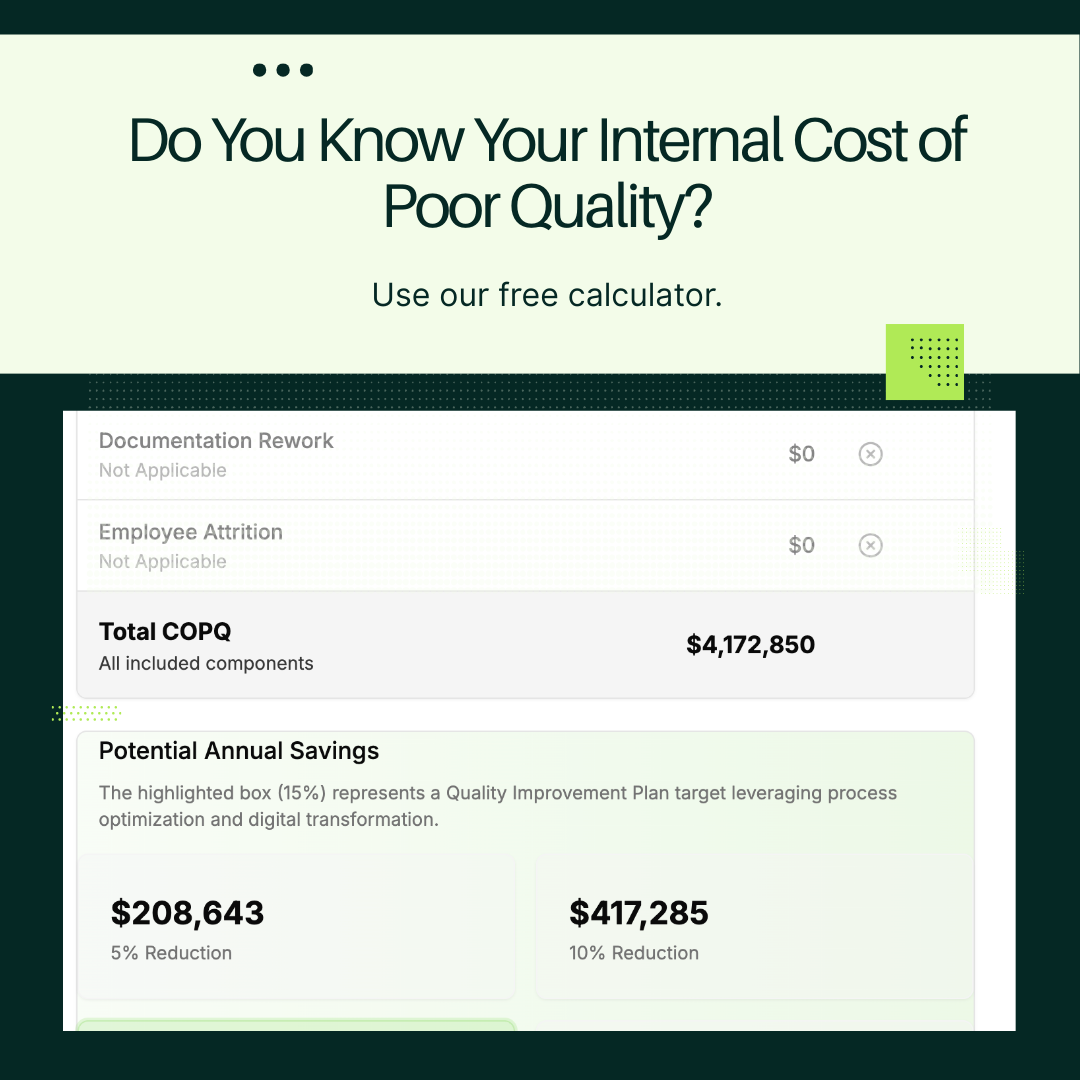

Calculate Your Cost of Poor Quality

Understand the financial impact of operational failures and how GMPKit can help you recover revenue.

Quantify Your COPQ Impact

Our COPQ calculator helps you understand the financial impact of batch failures, backlogs, and capacity constraints—providing the business case for operational recovery.

Proven Results Across Pharmaceutical Manufacturing

We've delivered measurable results across CDMOs, biopharma sites, and advanced therapy manufacturers— restoring operational stability when it matters most.

Backlog reduction in 90 days

Batch success rate improvement

Inspection readiness achieved

Successful scale-up completion

Industries We Serve

Global Experience, Local Execution:

Our team has delivered results across North America, Europe, and Asia—bringing global best practices to your local manufacturing challenges while working alongside your site teams.

Ready to Restore Operational Stability?

When your manufacturing operations are off-track and you need rapid results, let's discuss how GMPKit can deploy our proven approach to get your strategy back on track in 90-120 days.